|

Need a New Laboratory Water System?

We have many to choose from. We can save you thousands on

Complete Systems and replacement filters for most brands. |

All About Rotten Egg or Sulfur Smell Hydrogen Sulfide

Removing Hydrogen Sulphide Gas from Water (sulfur smell)

Also see : Bad Water Smells in Water Heaters

One of the best methods for dealing with this contamination is the The Terminator Chemical Free Oxidation and filtration sysytem.

| |

What is hydrogen sulphide?

Hydrogen sulphide (H2S) is a dissolved gas that gives water a characteristic "rotten egg" taste and odor. It corrodes piping, creates odors in the house, and turns water black. Homemakers will notice that it can change sterling silver to a black color almost instantly. H2S can cause odor problems at a concentration level as low as 0.05 mg/L.

H2S in well water

H2S often occurs naturally in well water, or can be caused by the presence of sulphate reducing bacteria in a well or water system. Since bacteria are the most common cause, treatment to control them should be tried first. Shock chlorination is the standard treatment for control of sulphate reducing and iron bacteria in a well (see Agri-fax 716 (D12) Shock Chlorination and Iron Bacteria Control ).

H2S in dugout water

H2S may also be present in dugout water, particularly during the winter and early spring. It is a by-product of decomposing weeds and algae and is caused by a lack of dissolved oxygen in the water. A good dugout maintenance program combined with dugout aeration will prevent this problem from occurring. (See Agri-fax 716 (B31) Dugout Maintenance and Agri-fax 716 (B36) Aerating Dugouts with Compressed Air ).

H2S in water heaters

Sometimes H2S may only be present in the household hot water. This condition is caused by a biochemical reaction between sulphates in the water, sulphate reducing bacteria, a magnesium rod in the hot water heater or organic matter in the water. If the odor problem in the water heater is caused by heat loving sulphate reducing bacteria, disinfect the water heater with chlorine bleach or hydrogen peroxide. Sometimes the reaction with the magnesium rod is the cause of odor problem. The purpose of the magnesium rod is to prevent corrosion of the water heater. Removing the magnesium rod will often prevent the odor problem, but will void the warranty and lead to the possible earlier deterioration of the tank. If corrosion is a concern, the magnesium rod can be replaced with a zinc rod. Try disinfecting the tank with chlorine bleach or hydrogen peroxide first before using any of the more drastic measures (See Agri-fax 716 (C33) Odor Control in Hot Water Heaters).

Water treatment options for removing hydrogen sulphide

Chlorination and sand filter

One method for removal of H2S is to install a chlorine feeder and a sand filter. The H2S is oxidized by the chlorine and any insoluble sulphide particles that form are removed by a sand or crushed anthracite filter. Approximately 2 mg/L chlorine must be added to remove 1 mg/L H2S. It may be necessary to install a small cartridge filter containing activated carbon on the drinking water tap to eliminate the chlorine taste. A full sized carbon filter is often used to remove the chlorine from the distribution system. This is an excellent alternative for situations where the water contains some iron along with the H2S.

Chlorination and activated carbon filter

The second method is to install a chlorine feeder and an activated carbon filter. As with the previous method, the H2S is oxidized by the chlorine and the insoluble sulphide particles are removed by the activated carbon filter. This filter also removes any residual chlorine that is left after oxidization of the hydrogen sulphide. An activated carbon filter requires a lower backwash rate than a sand filter, but a sand filter has a higher maximum service flow rate. This system is most appropriate in situations where there is only H2S present and no significant amount of iron. The chlorinator shown in Figure 1. is wired to the pressure switch so that the chlorinator is activated when the water pump switches on. The retention tank is installed to ensure sufficient mixing and contact time to complete the oxidation process. It should be large enough to retain water for at least 5 minutes at peak filter capacity (as a minimum, a 42 gallon retention tank is recommended). A valve should be provided at the bottom of the retention tank to drain any sediment. Chlorine test valves should be installed just after the pressure tank and just before the activated carbon filter. These are needed to help check the chlorine level in the treatment system.

Aeration

Aeration is accomplished by spraying water into a ventilated storage tank. The H2S is gas separated from the water as it is sprayed and drawn off as a gas by the ventilation system. Aeration will remove most of the H2S but chlorination may still be necessary. Some sulphide odors will remain due to the high pH of most Alberta waters. The lower the pH the better this system will work. A second pressure system is required to pump the water from the storage tank into the distribution system. Although they are not intended for the job, some aeration type iron filters have been used to successfully remove small amounts of H2S. There must be a much higher level of iron than H2S in the water for this to work successfully.

Manganese greensand iron filter

A properly maintained manganese greensand filter will effectively remove low levels of H2S, typically less than 2 mg/L. This type of filter oxidizes the H2S and filters out the resulting sulphide particles. It is very important that these filters have an adequate supply of water for backwash and are adequately regenerated with potassium permanganate. H2S requires 3 times the oxidizing power that iron does so the greensand filter must be regenerated more often than it would for an equal amount of iron. Manganese stripping, from the manganese greensand, can also occur. This stripped manganese can cause black staining. A chlorine feed system is usually the better choice.

Alternative systems

Other oxidizing agents besides chlorine can be added to the water to oxidize H2S. These include hydrogen peroxide, potassium permanganate, and ozone. Filtration will still be required after any of these have been added.

This article provided courtesy of Alberta Agriculture, Food and Rural Development.

| |

|

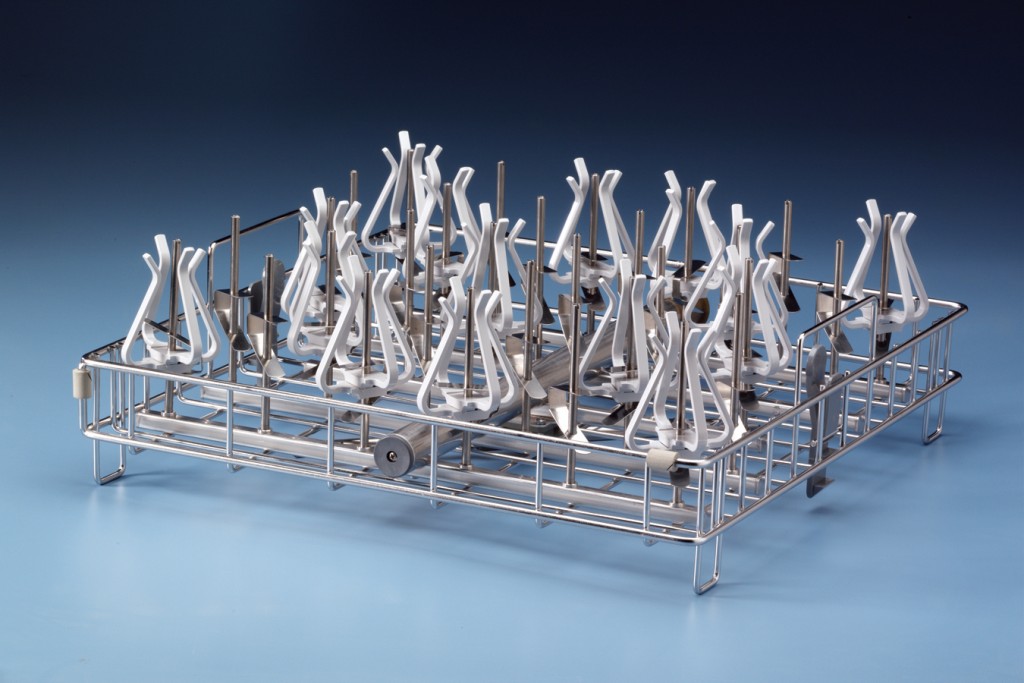

Images are representative of the products. Images may or may not be of the actual product. If it is important e-mail us for an actual image if available.

* Flat Rate UPS shipping when able to ship via UPS and is in the USA excluding Hawaii and Alaska.

Larger Items may not be able to ship via UPS, in that case freight charges will be quoted seperately.

International shipping will be quoted after the order is placed. You will have the opportunity to cancel before we finalize your order.

Terms and conditions

Credit Application

Privacy

Policy

List All Products

|